Home |

Up |

Next |

Prev |

Typical automotive thermostat

Car design is not what it used to be

When I was a young adult cars were relatively simple, moderately reliable and EASY TO WORK ON! They didn't have all the bells and whistles of today's vehicles but consequently they were cheap, there was less to go wrong, mechanics understood them better and anyone with a bit of common sense could fix them. But there was something else: They were designed to LAST and designed with COMMON SENSE!

You might think that because car manufacturers are multi-billion dollar international behemoths, their design engineers would be the best of the best and their designs would be informed by the wisdom of decades of immersion in the industry, peer reviewed and real-world tested to ensure their cars would be the best machines possible for the end user... You might think that but you would be WRONG! The truth is that the great marques of the world automotive industry are interested in one thing and one thing only: Profit! Profit at the expense of EVERYTHING else!

The design engineer's brief is NOT to build the best car. No! It is to produce the cheapest possible car that will sell the most copies. They are instructed to sacrifice common sense and good practice to do this. (They are also instructed to make it as difficult as possible to repair, but that is a different story.) So it is that we have idiot scrivets instead of sensible screws, jacks that don't work in real world situations, spare wheels that aren't road worthy, cylinders that are so close together that the gaskets between them routinely blow out, speedos that are 10% out, temperature gauges that don't display the ACTUAL coolant temperature, automatic gearboxes that do not change at the optimum point, making it impossible to find optimum power when required... The list goes on and on.

This article is about one such piece of stupidity which probably saves very little money but has a demonstrably BAD effect on your engine. This is the relatively recent practice of placing the thermostat at the bottom of the engine at the OUTFLOW of the radiator.

Car thermostats used to be on the top of the block

Until fairly recently coolant thermostats were ALWAYS at the top of the block, just before the hot water left the engine to enter the radiator. The idea is simple and sound:

Traditional thermostat (inside the chrome housing) at the top of the engine at the intake of the radiator.

- As the COOL coolant flows through the engine block it absorbs the excess heat of the engine and it becomes HOT.

- The HOT water is pumped upward but it also rises, so either way it gets to the top of the block.

- The HOT water passes through a thermostatic valve before passing into the radiator. If the water is HOT, the valve will stay open thus ensuring that there will be maximum circulation through the radiator until the water is COOL.

- The HOT water that enters the radiator is cooled by the passage of cool air over it as it makes it way down to the bottom of the radiator. It gets there because of the water pump and also because COLD water sinks.

- At the bottom of the radiator the water is relatively COOL. When the engine is hot this water will not be COLD but it will be substantially cooler that the HOT water at the top. You can easily check this for yourself by simply feeling the upper and lower radiator hoses.

- The COOL water at the bottom of the radiator flows into the engine block WITHOUT RESTRICTION and this cool water is pumped through the water jacket, cooling the engine and completing the cycle.

- If the engine is COOL, the water at the top will NOT open the thermostatic valve, the water will NOT circulate through the radiator and the engine will thus warm up to its optimum running temperature regardless of the external temperature. When the optimal operating temperature is exceeded enough water is let through into the radiator to return the block to optimum.

- Thus it is that the engine runs at a constant optimum temperature regardless of external conditions, (once it is warmed up), which prevents excessive wear and catastrophic failure.

As I said: simple and sound. You wouldn't think anyone would be stupid enough to disagree with this would you? Or if they did, you wouldn't think that any large international manufacturer would allow such stupidity to get beyond the design stage... would you?

Some idiot decided to put it arse-about

Sadly for the world, some idiot, probably Japanese, had the idea to go against common sense and put the thermostat at the bottom of the block, right at the cold water intake. Why he did this I can only surmise. Perhaps there was a saving of a few dollars? Perhaps it was to make space at the top? Perhaps he was just a FOOL who was well connected to the top brass? Anyway, it was a BAD idea. Let's look at what happens under this scenario:

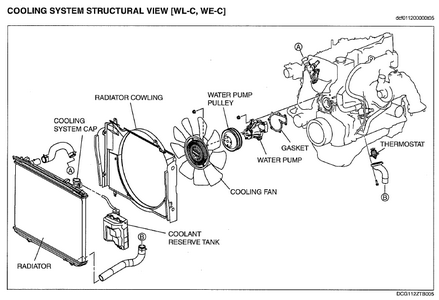

Mazda BT-50 cooling diagram. Note the thermostat placement at the bottom of the engine at the outflow of the radiator.

- As the COOL coolant flows through the engine block it absorbs the excess heat of the engine and it becomes HOT.

- The HOT water is pumped upward but it also rises, so either way it gets to the top of the block.

- The HOT water can only enter the radiator if the thermostat at the bottom of the block is open. It will sit there growing hotter and hotter until this happens.

- The COLD water at the bottom of the radiator attempts to enter the engine block but it can only do this if the thermostat is open. It will sit there until this happens.

- The water surrounding the thermostat at the bottom of the engine is COOLER than the water at the top because HOT water rises. Yes, there is still bypass circulation of coolant around the block thanks to the water pump but it is not as effective at the thermostat as one might wish. Nevertheless, eventually it is hot enough to allow the thermostat to open.

- The COLD water from the bottom of the radiator passes through the thermostatic valve, cooling the mechanism and CLOSING the valve, even though most of the water in the jacket is HOTTER than required to open the thermostat.

- Once the valve is closed the surrounding water warms it back up again and it opens again briefly, only to be closed again by the COLD water from the radiator. Thus you get only dribs and drabs flowing through system instead of the hi-flux cooling that is required.

- Because there is little flow through the radiator the bottom hose is truly COLD, exacerbating the situation in a positive feedback loop.

- Eventually the coolant temperature at the bottom of the block will be so HOT that it can hold the thermostat open despite the cold water entering and you will get decent circulation, but this will not happen until the block is running 20°C above optimal.

The effect of this arse-about placement is that, depending on the ambient temperature, the engine may run dangerously hot, not above the safe level but close to it. This may not damage the engine in itself but it leaves much less margin of error for any additional overheating problems that might arise. Under such a scenario the pressure cap on the radiator will quickly blow, ejecting your coolant and cracking your nice aluminium head. Then you can curse the idiot that thought this was a good idea!

Another effect of this stupidity is that the engine temperature, depending on the ambient temperature, will not be constant, but will cycle up and down by up to 20°C. This cyclic change in temperature is unlikely to be a problem in the short term, but over the long term may cause cracking in the head. Once again, some idiot design engineer is responsible for thousands of dollars of your money going up in steam!

Note: This situation only happens if the ambient temperature is cool enough to produce sufficiently COLD water at the bottom of the radiator. Say below 25°C. If the ambient temperature is warm or hot (say, over 30°C), then the water at the bottom of the radiator will not be cold enough to shut the thermostat off and the system will work just fine.

How I found out about it

In 2012 I bought a Ford Ranger (2009 model), the same car as the Mazda BT-50; a Japanese designed car built in Thailand. It drove well and exhibited no problems until the day that, out of nowhere, the temperature gauge jumped into the red and I had to stop the car. The radiator was empty! It turned out that this was because of the corrosion of the cooler for the idiot Exhaust Gas Recirculation. (This is another design abomination which I may deal with elsewhere at a later stage.)

The effect of that design flaw was that the engine developed a tiny crack in the head which was impossible to diagnose except by replacement of the head, (an expensive exercise). One thing I learned in discussion with a friend who worked on instrumentation design for the automotive industry was that the coolant temperature gauge on the dashboard does NOT display the actual temperature! He told me that because people get worried when the needle isn't in the middle, the software that controls the gauge simply places the needle in the middle unless it's really cold or really hot. The effect of this condescending and wrong-headed policy is that you don't know you have an over-heating problem until the radiator cap is about to blow. By then it will quite likely be too late to do anything about it. To get the correct temperature reading you need to buy an after-market analog gauge or simply connect to the OBD-II digital bus that runs the car and get the information that way. I did this with a Scan Gauge II.

A typical dashboard temperature gauge.

In 2014 after a trip up north I noticed that the engine ran cooler in the heat of the Mallee at 35°C than it did on the temperate coast at 20°C... at least 10°C cooler! Surely hot weather should mean hot engine? How can one explain such an artifact? I scratched my head and cogitated but I couldn't think of an explanation. This is not surprising, considering that no one talks about this flaw and that it is a little complex to get to the bottom of.

I took my car to a local radiator specialist who grossly overcharged me for flushing out the radiator and changing the thermostat but there was no real difference in behaviour. I took the car for a series of test drives. When the engine was properly warm the Scan Gauge temperature read over 100°C which I was sure was too high. The thermostat is supposed to be fully open by 95°C so therefore that should be the maximum temperature under normal conditions. I noticed that the bottom hose of the radiator was as cold as it was before starting the engine. If the thermostat is working properly and the gauge is over 100°C the lower hose should NOT be properly COLD!

Obviously there was a problem so I decided to take matters into my own hands. I hate having to do this but so often the so-called professionals simply can't do a proper job and/or don't have the brain to diagnose a tricky problem regardless of all their experience. Firstly I removed the old radiator and installed a new one. No thanks to the bastards that designed the car as their insufficient manual and their idiot scrivets made the job FAR harder than it ought to be. I examined the water pump which was pristine.

To my considerable disappointment another test drive revealed no difference. But as Sherlock Holmes said: "Once you eliminate the impossible, whatever remains, no matter how improbable, must be the truth." There was only one possibility remaining: the thermostat! But the thermostat had just been replaced. How can it be the problem? So I removed the thermostat. Again; no thanks to aforementioned bastards here for making a trivial job into a real pest. I needed almost 2 feet of socket extensions to reach the screws holding the thermostat housing in a place where it is virtually impossible to get to. Considering this used to be easily accessible at the top of the engine I think the people responsible should spend time in jail for the pain and suffering they have caused to thousands of innocent motorists with their amoral, oppressive stupidity.

Anyway I took the car for a drive sans thermostat and lo! My scan gauge showed a max coolant temperature of 69°C with aircon off and 71°C with it on. With the thermostat in I had been running between 88°C and 105°C. The system was at least 20°C cooler and far more constant.

I put the thermostat in a pot of water on the stove and checked its operation. Sure it enough it performed according to spec: It started to open at 82°C and was fully open by 95°C.

It was hard see the problem since all the components were working fine, but what I KNEW was that the thermostat was not working correctly in the car, even though it was fine on the stove. After much cogitation and research I formed the hypothesis that I have detailed above. But how to test it?

What I did about it

The Martian solution: Inline thermostat installed.

My conclusion was that the thermostat belonged at radiator intake, but the car was not designed that way so what could I do? I thought I would detail my problem and desired solution to an online forum specialising in my car. Well that was a mistake as you can read here. It is a sad indictment on the human race that pretty much ALL forums that are supposedly set up to help people with a common interest communicate their ideas, share their stories and ask for help are inevitably populated by small-minded people with a little knowledge who view the forum as their fiefdom. They gather a selection of vocal supporters and set about shutting up anyone who disagrees with them and doesn't kowtow to their overlordship. If that doesn't work they petition the board admin to ban the dissenter. This thread is a good example of the situation but it is certainly not the only board that has treated my politely phrased, theoretically sound and evidence based ideas like this.

After receiving only infantile suggestions and ridicule from the so-called experts on various forums I dreamed up the idea of an inline thermostat that I could mount in the middle of the top hose. I searched online for a suitable housing and eventually EUREKA! I found the exact item here at JEGS, an American car parts store in Columbus, Ohio. It fits standard GM thermostats which I had no trouble sourcing here in Australia.

When the item arrived I had no trouble installing the thermostat into the housing, cutting 2" out of the top hose, fitting in the new unit and clamping it home. I then took the car for a drive in identical conditions and along the same route as I did when I tested the system under the other thermostat situations. I now had 3 scientific results:

- Mazda thermostat placement: 100°C

- No thermostat with aircon: 71°C

- Inline thermostat with aircon: 84°C

Thermostat in place in half housing.

At this point I found the hypothesis proven and had no hesitation in documenting it on the forums and giving the small-minded knockers a piece of my mind. There WAS one problem though: Due to the fact that there is approx 5 cubic inches of static water between the wax pellet of the thermostat and the water circulation path in the block there was significant hysteresis whenever the thermostat closed right off and needed to open again. Because there was no coolant circulation right to the pellet it took a while for CONDUCTION through the water to heat the thermostat until it opened and the water from the block flowed through it again. This delay was 10-20 seconds in my case causing a brief temperature rise up to 95°C before the valve opened and the coolant temperature rapidly returned to 84°C.

This hysteresis only occurred when the valve had been fully shut, as any passage of coolant through the thermostat keeps the circulation going and the pellet at the temperature of the coolant in the block. The problem was most pronounced in driving around town with stopping and starting, up and down hills etc. One might argue that this does not appear to be a significant problem as the temperature spikes only last 10 seconds and they are only 95°C anyway which is less that the standard Mazda setup. Nevertheless I tried to find a solution to this final difficulty.

In order to keep the thermostat pellet at the same temperature as the coolant at the top of the block it is only necessary to keep some small flow through the thermostat at all times. A couple of small holes drilled in the thermostat flange should do the job I guessed.

The thermostat with 2 small by-pass holes drilled in the flange.

So I drilled those holes put the system back together and took the test drive. The system now ran at 80°C under light load conditions instead of the 83°C without the holes. Under load the thermostat now responded much more quickly to increased block temperature and even when the valve had been fully closed the system did not spike any higher than 85°C before returning to the 82°C that is the new normal running temperature. Voila! PROBLEM SOLVED! No thanks to the knockers on the online forums, most of whom were only interested in cutting down the tall poppy, not in examining facts with an open mind. But in the end it was THEY who were cut down!

Epilogue

The nay-sayers, tall-poppy cutters and Mazda fanbois can say what they like, but I have solved my problem and I believe that my results prove conclusively that placing the thermostat at the engine block intake is a MISTAKE!

I have driven my Ford Ranger for more than 4 years since I performed this mod without an issue and have been to the top of Cape York, driven across the Gulf Country, up the Birdsville track and around Victoria various times under all conditions and the coolant temperature has been rock-steady on 84°C the great majority of the time. Only under high engine load, (such as climbing mountains fully loaded at 100kph), has the temperature spiked to 95°C. Highway speeds in hot weather also takes the temperature in the 90s but these temperatures are well within spec and have plenty of headroom before alarm bells should start ringing.

To anyone that wishes to perform this mod I can recommend the inline housing I linked to previously. There is also another make that JEGS supply if you want to try something different. I recommend keeping the housing as close to the engine block as possible to minimise the convection lag. The constant baseline flow afforded by the small bypass holes in the thermostat will lower the operating temperature in temperate conditions by around 3°C so buy a thermostat rated about 3°C above the standard. Ie buy an 85°C job.

Unless your engine has radiator hoses of 35mm you will also want some hoses that reduce in diameter from one end to the other. In my case the housing I used had a flange diameter of 35mm and the standard hoses were 38mm. One of these will need a 90° bend. After much searching I discovered that Motorsport Accessories supply the necessary reduction hoses (with and without a bend). You can order them here.

Finally: Don't forget to remove the existing thermostat but leave the rubber gasket in place and don't forget to check for leaks! UV dye (and torch) is a good way to find any.

Excelsior!

UV dye and torch bought via eBay. Just add to your coolant and check for leak residue in the dark.

Warren Mars - March 8, 2019